Creaflow is a start-up company based in Deinze, Belgium. Creaflow's mission is to provide innovative and scalable flow reactors that address the unmet needs of customers in the pharmaceutical, life science and specialty chemicals industries. It has consistently developed and manufactured scalable flow reactor technology that has pushed the boundaries in photochemistry, electrochemistry and multi-phase chemistry.

Creaflow’s flagship product is the HANU™ Flow Reactor, which originated from a research collaboration between Ecosynth and Ajinomoto Bio-Pharma Services. This innovative flow reactor offers a number of advantages over comparable products. These include a high mixing capacity no matter the flow rate; linear scalability by simply widening the process channel; and high customization potential. All without compromising energy or mass transfer while improving process control.

HANU™ flow reactors

HANU™ flow reactors are assembled in a modular fashion allowing companies to build the ideal reactor configuration to accommodate their chemistry. As such, the HANU™ flow reactor unlocks hard-to-perform chemistries that are traditionally difficult to scale.

Expanded product range

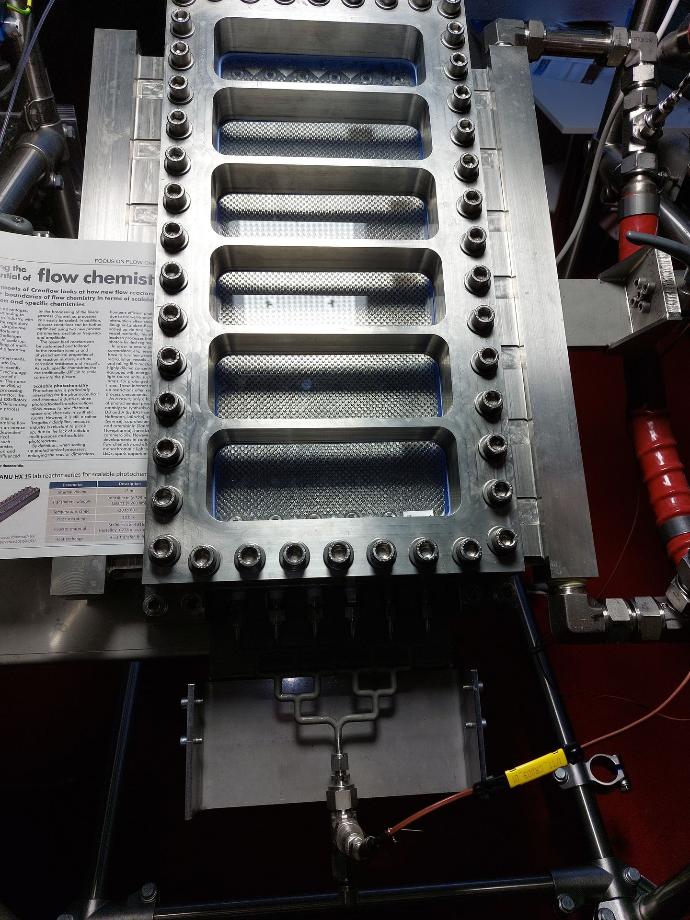

To further scale the photochemical process, Creaflow developed the HANU™ HX 150 Flow Reactor. By widening the process channel, the internal volume is increased from 15 ml to 150 ml. However, all crucial process characteristics – process path length, irradiation properties, mass and heat transfer, residence time distribution and so on – remain unaffected.

HANU™ HX 150 Flow Reactor

HANU™ HX 150 Flow ReactorIn June 2021 Creaflow launched the 2nd generation of HANU™ Flow Reactors. The HANU™ 2X Flow Reactor pushed the parameter boundaries further by offering expanded temperature and pressure capabilities. In addition, a downsized version, the HANU™ 2X 5 Flow Reactor (with an internal volume of 5 ml), was released to allow the technology to be used during the laboratory R&D phase.

Manetco called in

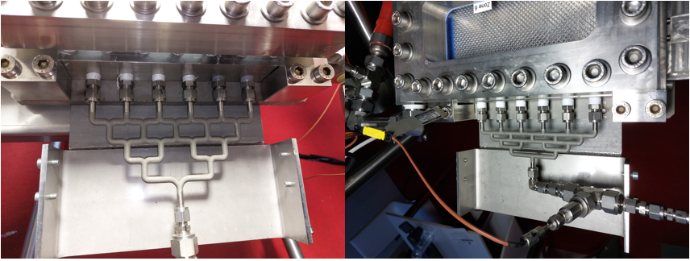

The next development was to scale up reactor capacity. This meant increasing the number of inlets and outlets to maintain smooth and efficient flow control. The obvious solution was to use six pumps in parallel. However, Creaflow wanted to avoid this and were therefore looking for a way to produce a custom manifold that would distribute the flow evenly over the entire reactor.

Manetco was contacted to come up with a feasible solution. Based in Belgium, Manetco specializes in helping start-ups, research labs and industrial facilities overcome challenges and obstacles in their R&D labs and pilot plants by designing and making custom parts, sensors and equipment.

“Based on a sketch from the engineer’s idea and after many iterations in close collaboration with our customer, we designed and manufactured a custom manifold exactly adapted to the requirements of their application,” said Tanguy Van Regemorter from Manetco. “We made the manifold in 3D printed stainless steel. The design was especially sturdy to provide uniform and equal flow from each of the six outlets in order to ensure optimal control of the process.”

3D printed manifold in stainless steel

Creaflow presented their new HANU™ Flow Reactor at Achema, in Frankfurt, in August 2022.

HANU™ HX 150 Flow Reactor presented at Achema

Are you looking for a custom part for your process or pilot project ? Contact us. We will be delighted to discuss your specific requirements and propose a suitable solution.

Manetco develops a 3D printed manifold to help Creaflow scale up photochemistry