High Precision Metering Pump

Overview

Fuji's Super Metering Pumps are designed for high precision fluid transfer with a flow reproductibility around 0.1%. These pumps are engineered to provide precise delivery of liquid without the occurrence of cavitations and pulsations.

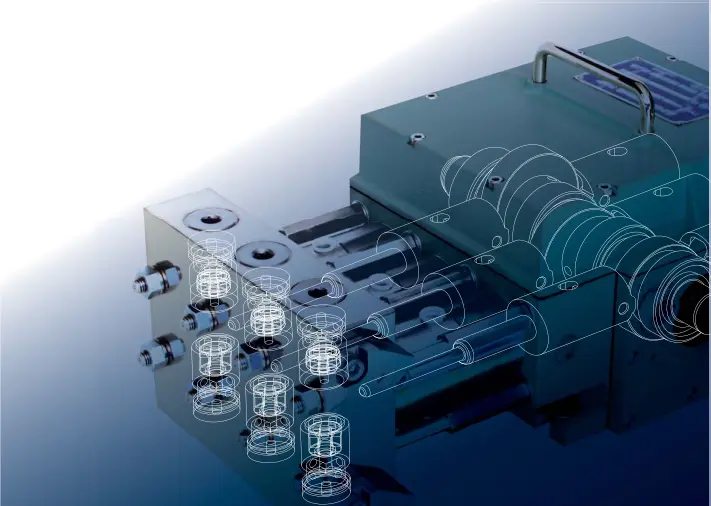

At the heart of every Fuji-Techno Super Metering Pump is a specially designed cam that controls the motion cycle of the three plungers. The three plungers work in perfect equilibrium with each other. The timing of each plunger’s suction and discharge cycle is precisely controlled by the cam, so that the total liquid discharged from the pump is accurate and constant with no pulsations in the flow.

The plungers are designed to make different motions in six stages within one revolution of the cam and in harmony with each other. For example, the first plunger starts its discharge stroke with the cam at 0°, the second plunger starts at 120°, and the third at 240°. It is this unique operation that ensures constant flow with no pulsations. An electric motor is used to drive the cam-shaft.

The resulting motion of the plungers, creating suction and discharge cycles, effects the delivery of the liquid. The liquid being pumped enters and exits the pump head through suction and discharge valves.

Key Features

- High Accuracy: Fuji's Super Metering Pumps provide exceptional accuracy in fluid delivery, ensuring consistent performance even in demanding environments.

- Durable Construction: Built with high-quality materials, these pumps are designed to withstand harsh conditions and offer a long service life. The pump heads is built in various materials, both metal and metal-free. These include the standard stainless steel (316) type, stainless steel (316L), Hastelloy (C-22) and also Titanium metal versions, as well as the metal-free heads in PTFE and PEEK.

- Versatile Applications: Suitable for various fluids, including highly viscous and corrosive substances, making them adaptable to multiple industrial needs. It can also work with pressure between 98 bar and up to 2000 bar for specific models. The slow movement of the plungers prevent the risk of cavitation and allow to work with low viscosity fluid like, for example, acetone at 60°C without creating bubbles. .

Applications

Fuji's Supermetering Pumps are ideal for:

- Continuous mixing and emulsification: A stable volume of liquid can be transferred smoothly without any pulsation. By utilizing one of Manetco's continuous mixers, emulsification and mixing can be performed instantly in the feedline, which eliminates the requirement for batch systems or pre-mixing stages.

- Additive feeding relative to the extruder: The discharge flow rate remains unaffected by pressure changes, as the pump operates without pulsation and is resistant to variations in load.

- Accurate coating: Uniform coatings can be achieved due to the non-pulsating nature and constant volume of the system. The pump's performance is not compromised by pressure fluctuations from changes in the suction head or clogged filters. Additionally, there are no air bubbles introduced in a floating layer. This pump is particularly beneficial for continuous coating processes like dip coating and roll coating.

- Precision in washing, spraying, and spray drying: Thanks to the absence of pulsation and the maintenance of a constant volume, particle diameters remain consistent. Even with low-viscosity fluids, pressure variations do not significantly affect performance. This pump is ideal for combustion testing applications.

Let's Connect

Contact us to receive the datasheets. We can also plan a call to help you identifying the right model.

Precise Flow with High Precision Metering Pump

Video showing the stable flow obtained with the Fuji pumps.