Certech is a Belgian Research center working on process intensification. This methodology improve the safety, efficiency and yield during a production process of chemicals, pharmaceutical compounds, etc.

Within the framework of the Intense4Chem projects portfolio

funded by the European Regional Development fund (ERDF), Certech is

developing continuous flow reactors to achieve the hydrothermal

synthesis or treatment of inorganic particles. Using continuous reactors

allows reducing the size of the installations, intensifying the heat

and mass transfer and eliminating the “dead times” related to the

feeding, heating, cooling and discharging cycles inherent to a batch

process. The safety, the overall efficiency of the process and the

product characteristics are as such significantly improved.

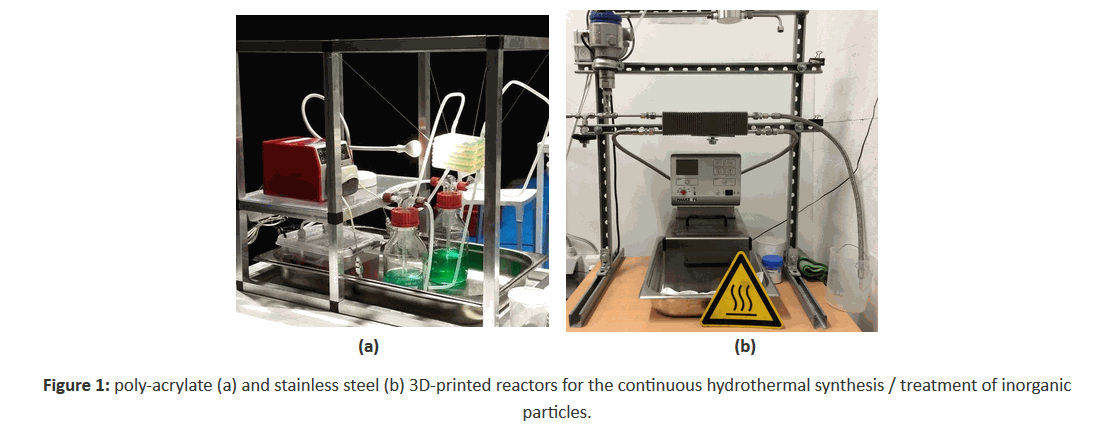

Manetco collaborated with Certech on the development of this new continuous reactor. A transparent version is used to validate the fluid dynamics (Figure 1a). The design is then reproduced in stainless steel to perform the experiment in real condition with a resistant material to high temperature, pressure and agressive chemicals (Figure 1b).

Additive manufacturing is an efficient technology to build up compact continuous reactors designed to promote intense mixing and high heat

transfer rates.

Do you need to create a new continuous reactor ?

Contact us, our experts will be happy to give your advices.

New continuous reactor for process intensification