Mateo Berton, from Lebsa, is working on the development of a production process and he faced a challenging mixing issue. To develop the process he designed a home-made set-up and, for the mixing step, he used simple T-union 1/8''. Unfortunately, this type of mixing union wasn't enough for his process which involves neat reagents and highly viscous product - inducing poor mixing efficiency with a rather high pressure drop.

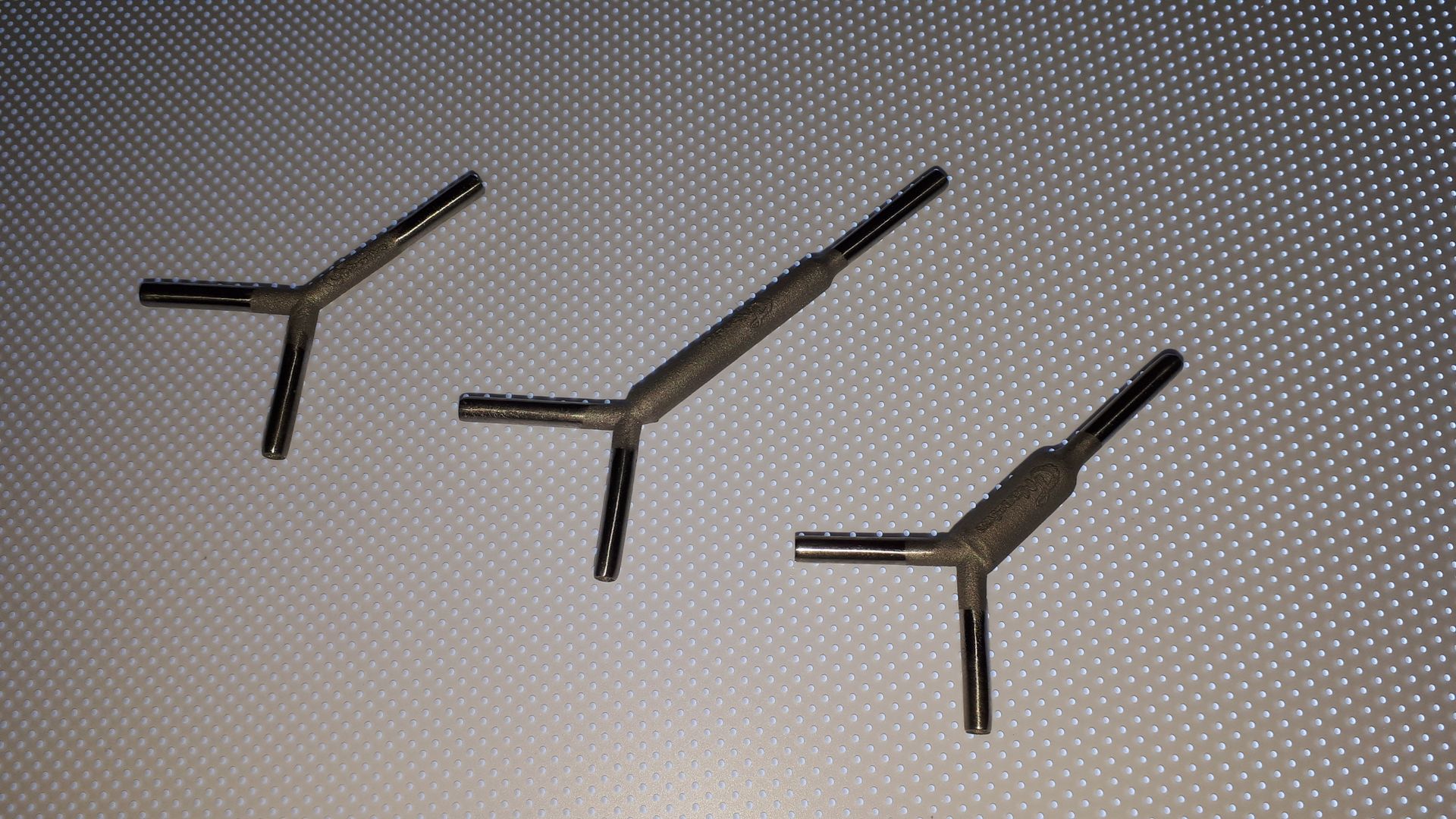

We proposed to Mateo to test some of our off the shelf static mixer with integrated efficient mixing elements and a design which limit the pressure drop. He tested the three mixers represented in the picture below and he identified the best design for his experiment.

The mixer drastically improved the mixing efficient while keeping a low pressure drop. These excellent results encouraged him to test their process at larger scale. We adapted the design to create a mixer with a larger inner volume adapted to higher flow rates.

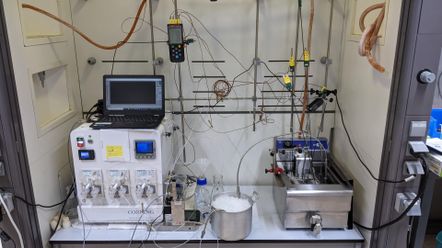

The final mixer, in stainless steel, is represented in the picture below in the middle of the other tubes used for the set-up. This up-scaled deisgn also showed excellent mixing efficiency with low pressure drop at higher flow rate.

With this mixer, Lebsa’s prototype, built in 1/4 inch OD tubing, can generate up to 2 kg/h of API intermediate.

Mixer connected to the tubing

Final Lebsa's prototype

Are you facing challenging mixing steps to develop a new process ?

Feel free to call us and we will be happy to imagine solutions.

Process up-scaling simplified for Lebsa