Design and Operating Principles

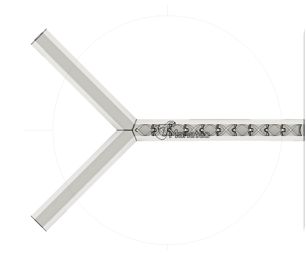

The Spiralmixer is a micromixer with helical element design that has set industry standards since 1965. Its operation centers on a fundamental mixing principle:

- Alternating right-hand and left-hand helical elements direct flow radially toward pipe walls and back to center

- Each element creates velocity reversal and flow division

- All material undergoes continuous and complete mixing

- The design effectively eliminates radial gradients in temperature, velocity, and material composition

The mixer's geometry maximizes efficiency while minimizing restrictions, avoiding the wasted energy and material blockage typically found in more restrictive motionless mixers

This mixer is adapted for application where low pressure drop is required.

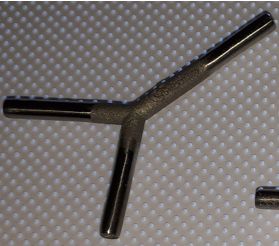

The Spiralmixer can be designed with with various inlet and oulet number. The innder diameter of the inlet can be fine tuned to fit the need of the application for applications with multiples ratios.

The outer diameter can be varied between 1/16'' to 1/2''. It is also available in metrics.

The Spiralmixer is also available as stand alone static mixer which can be fitted into tubes.

Material available: Biocompatible PMMA - Stainless steel 316L - Hastelloy - Other materials (like copper, nickel ... on request)

Compatible with various type of connector like Swagelok, HPLC ...